Application scope:Food industry, mining equipment, sewage treatment, battery materials, energy and environmental protection, non-metallic minerals, waste sorting, pharmaceutical industry, etc

1、 Explanation

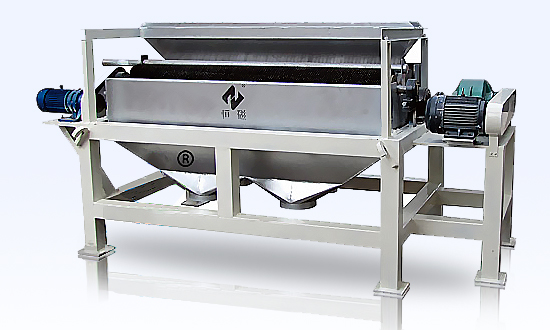

The QCG wet roller magnetic separator is a combination model developed by our company based on years of experience and customer on-site requirements. It can achieve multiple structures or combinations of different magnetic field strengths. The principle is that the material enters the magnetic field area through the material bin and the guide plate. The magnetic minerals are adsorbed on the surface of the magnetic roller and rotate to reach the concentrate area. The brush removes the magnetic minerals adsorbed on the surface of the magnetic roller and drops them into the concentrate hopper under the spray of high-pressure water. Some of the unadsorbed magnetic particles, non-magnetic particles, and weakly magnetic particles enter the next stage for further selection. At most, a combination of 10 rollers can be achieved, which can separate the material up to 10 times, especially for strong magnetic, medium magnetic, and weakly magnetic coexisting minerals with significant sorting effects.

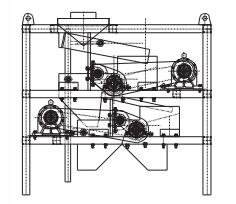

2、 Schematic diagram

3、 Scope of application

Mainly used for coarse selection, scanning selection, and fine selection of fine-grained weakly magnetic ores. It can effectively remove iron from manganese ore, hematite, pseudohematite, specularite, siderite, manganese ore, chromite goethite, limonite, siderite, chromite, niobium tantalum iron ore, titanium cerium iron ore, scheelite, itabirite, apatite, yttrium phosphate, olivine, chalcopyrite germanium ore, iron white stone, biotite, epidote, serpentine, primary ilmenite, coastal sand ore, primary rutile, scheelite, and non-metallic minerals.

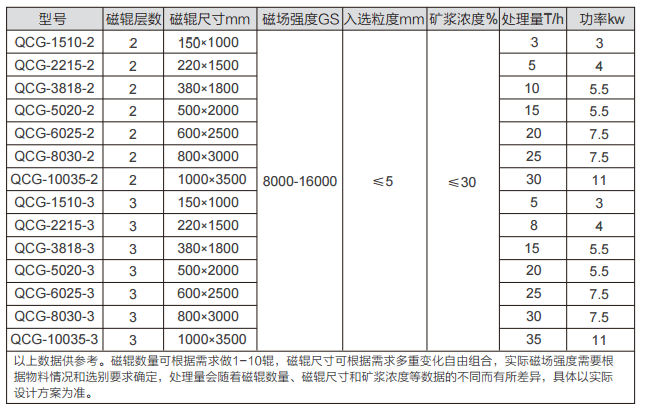

4、 Main technical parameters

5、 Industry Applications

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Mobile:+8618553633270

Mobile:+8618553633270

Tel:0536-8339337

Tel:0536-8339337

Email:sdhcjx1@gmail.com

Email:sdhcjx1@gmail.com

WhatsApp:+8613963654232

WhatsApp:+8613963654232