Application scope:Food industry, mining equipment, sewage treatment, battery materials, energy and environmental protection, non-metallic minerals, waste sorting, pharmaceutical industry, etc

1、 Explanation

Our company's HJLH wet vertical ring high gradient magnetic separator belongs to independent innovation and research and development, and has obtained a national utility model patent.

Its technological innovation adopts simple and easily accessible water as the cooling medium, and the excitation coil uses thick hollow tube wires. The water flow directly passes through the center of the hollow tube wire, and the heat of the coil is conducted to the water in the most direct way, using the rapid circulation of the water flow to take away the heat.

Using patented technology, it completely avoids the formation of scale during the water flow process, completely solves the problem of pipeline blockage, and enables the equipment to maintain long-term stable operation.

The excitation coil is wound with a magnetic pipeline with patented technology, advanced insulation technology, and the performance of the material ensures the service life of the coil.

Magnetic media have independent intellectual property rights and are made of imported materials. Through independent design and research and development experiments, they can generate high gradient magnetic fields with an induced magnetic field strength of 2T.

It converts electrical energy into magnetic energy based on the principle of electromagnetic induction, and has the characteristics of large processing capacity and high efficiency. This machine is suitable for mineral processing plants with high requirements for processing capacity and purification rate.

This machine achieves the purpose of iron selection by generating a strong magnetic field through a sorting ring. The magnetic field can be adjusted appropriately according to the magnetism of iron in the ore, making it flexible to use. Compared with traditional magnetic separators, it also saves some energy.

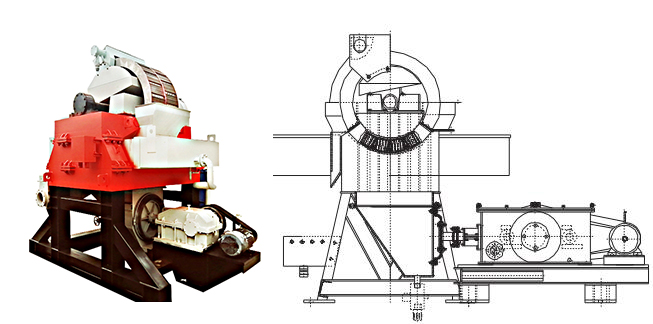

2、 Schematic diagram

3、 Scope of use

The HJLH vertical ring high gradient magnetic separator is suitable for wet separation and magnetic separation of fine weakly magnetic minerals with a mesh size of around -200, and can also be used for magnetic separation and iron purification of non-metallic minerals. For example:

◇ Black metal: recovery of pseudo hematite, hematite, limonite, siderite, manganese ore, etc.

Non ferrous metals: separation of minerals such as scheelite and garnet.

Rare metals: recovery of ores such as tantalum niobium iron ore, iron lithium mica, monazite, and yttrium phosphate ore.

Purification and removal of non-metallic materials such as quartz, feldspar, kaolin, and refractory materials

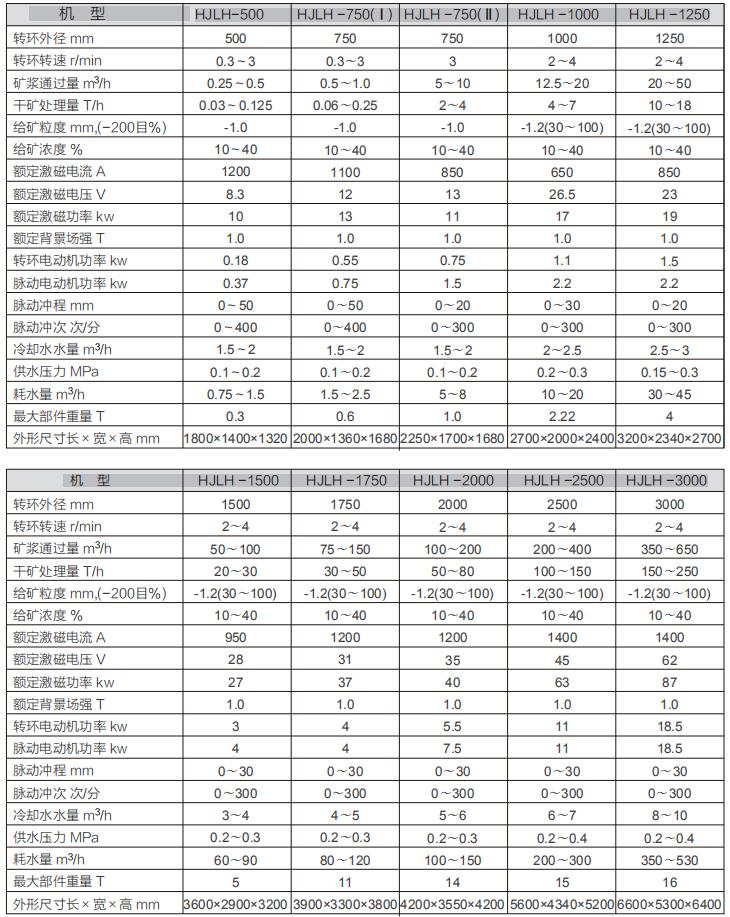

4、 Main technical parameters

5、 Selection

The selection of this equipment is generally based on the slurry passing capacity. In practical applications, when sorting minerals, the mineral processing indicators may be affected by different slurry concentrations. To obtain better mineral processing indicators, the slurry concentration can be appropriately reduced according to actual needs. When the proportion of magnetic materials in the sorted minerals is too high, the processing capacity of the whole machine will be limited by the magnetic medium area and the total amount of adsorbed magnetic materials. Therefore, the ore concentration should be appropriately reduced to obtain better mineral processing indicators.

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Mobile:+8618553633270

Mobile:+8618553633270

Tel:0536-8339337

Tel:0536-8339337

Email:sdhcjx1@gmail.com

Email:sdhcjx1@gmail.com

WhatsApp:+8613963654232

WhatsApp:+8613963654232